Ice fire board, also known as polyester fiber cement board or clean board. (also called Fiber Cement Insulation Boards /FC sheeting/ Fiber Cement Board /Inorganic pre coated board/ fireproof board and clean board/Polyester Fibre Panels)

It is mainly made of siliceous and calcareous materials, and cured by various methods. It is composed of asbestos free fiber cement board as the base board, adhesive layer, and impregnated paper (impregnated paper is a decorative paper impregnated with resin adhesive). It is a type of board made in the form of ice and fire, with waterproof and fireproof characteristics, and can achieve the decorative effect of real marble. It belongs to the technical field of building decoration materials.

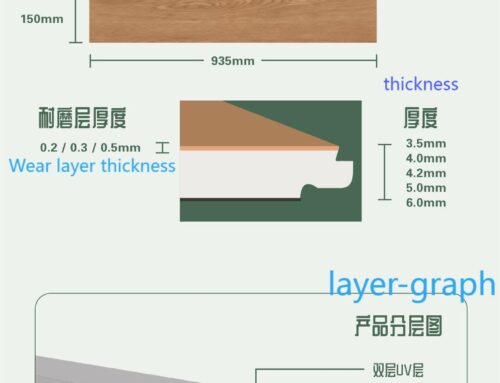

Product specifications: Thickness 3mm-12mm; Specification 1220mm * 2440mm

Product materials: Fiber cement board, impregnated paper, other materials

Product features:

Fireproof insulation: Non combustible Class A, the board will not burn and will not produce toxic smoke in the event of a fire; Low conductivity makes it an ideal insulation material that can effectively reduce losses.

Waterproof and moisture-proof: Its stable performance in semi outdoor and high humidity environments prevents the product from sinking or deforming.

Thermal insulation and sound insulation: Low thermal conductivity, good thermal insulation performance, high product density, and good sound insulation.

Lightweight and High Strength: The sheet material pressurized by a 5000 ton flat hydraulic press not only has high strength, but also is not easily deformed or warped.

Easy construction: lightweight, easy to construct, convenient to install, can effectively shorten the construction period.

High cost-effectiveness: Low price, convenient transportation, and lower transportation costs compared to decoration materials such as marble.

Economic and aesthetic: lightweight, in combination with the keel, effectively reducing construction and decoration costs; The appearance color is uniform and the surface is flat. Direct use can make the color of the building surface uniform, which is both economical and beautiful.

Color stability: The color of the ice and fire board can withstand the test of time and will not change color.

Safe and harmless: below the national “Radiation Health Protection Standards for Building Materials”, the measured indicators are equal to the lawn values 20 meters away from surrounding buildings.

Durable: It is not easily corroded by acid or alkali, and will not be damaged by moisture or insects. Moreover, its strength and hardness increase over time, resulting in a long service life for the product.

High utilization rate: secondary processing can be carried out according to the actual situation, including sawing, drilling, carving, nailing, painting, pasting ceramic tiles, wall coverings and other materials.

Application scope:

Commercial buildings: Business buildings, entertainment venues, shopping malls, hotels

Industrial buildings: chemical plants, food processing workshops, pharmaceutical factories

Residential buildings: prefabricated buildings, ordinary home decoration, villas

Public places: airports, train stations, hospitals, theaters, passenger stations, tunnels, sports halls, exhibition halls, etc.

Ice and fire board can be used to create various exterior walls, interior decoration, store decoration and other places. It is a popular covering material that makes people feel both beautiful and unique.

Leave A Comment