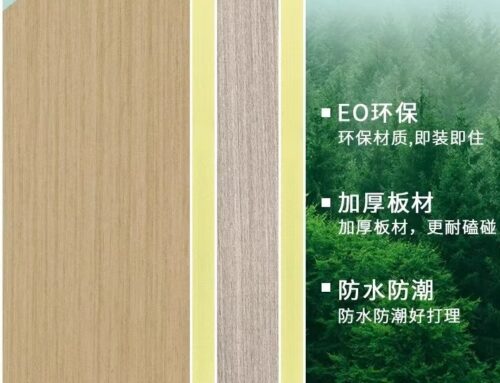

bamboo charcoal wall panel are mainly composed of materials such as carbon crystals, resin, and glass fibers. Carbon crystal, as the core component, endows bamboo charcoal wall panel with numerous unique characteristics.

Carbon crystal panels have good sound insulation effects. It can effectively isolate the interference of external noise and create a quiet and comfortable living and working environment for people. According to relevant data, the sound insulation performance of carbon crystal panels can reduce noise by more than X decibels.

At the same time, bamboo charcoal wall panel are resistant to acid and alkali, as well as UV radiation. Under harsh environmental conditions, bamboo charcoal wall panel can maintain stable performance and are not easily corroded by chemicals and damaged by ultraviolet radiation. Long term use will not cause problems such as deformation or fading.

In terms of conductivity, bamboo charcoal wall panel have certain advantages. It can quickly conduct current and play an important role in some specific application scenarios. For example, in heating systems, carbon crystal panels can efficiently convert electrical energy into thermal energy, achieving rapid heating.

Thermal stability is also a major advantage of bamboo charcoal wall panel. It can maintain stability in environments with large temperature changes and is not easily deformed. Whether in cold winter or hot summer, bamboo charcoal wall panel can maintain good performance.

In summary, bamboo charcoal wall panel, with their unique material composition, exhibit various characteristics and advantages such as sound insulation, acid and alkali resistance, UV resistance, conductivity, and thermal stability, laying a solid foundation for their widespread application in various fields.

2、 Application scope of carbon crystal plate

(1) Construction field

Carbon crystal panels have a wide range of applications in the field of construction. It can be used for exterior wall decoration of buildings, greatly improving the aesthetics and safety of buildings due to its high strength, fire resistance, waterproofing, anti-corrosion, and resistance to deformation. The unique texture and color add a modern feel to the building, making it more attractive in appearance. At the same time, carbon crystal panels can also be used for decoration and protection of walls, floors, roofs, and other parts. In terms of wall decoration, it can create a unique atmosphere for indoor spaces; In ground applications, its wear-resistant and corrosion-resistant properties can withstand daily wear and various environmental factors; When used on roofs, it can effectively prevent water and heat, providing better protection for buildings.

(2) Public domain

In the public domain, carbon crystal panels are very suitable as promotional billboards in public places. It has the characteristics of high definition and high brightness, which can attract people’s attention. Whether in shopping malls, subway stations, airports, or other places, promotional billboards made of carbon crystal panels can display information with their vivid colors and clear images, achieving a good promotional effect. In addition, the durability of carbon crystal panels also enables them to be used in public places for a long time, reducing the cost of replacement and maintenance.

(3) Interior decoration

In terms of interior decoration, carbon crystal panels can be used for interior wall, ceiling, furniture and other decorations, which can greatly enhance the beauty and comfort of the interior. Multiple colors and patterns are available to meet the decoration needs of different styles. When used for wall decoration, carbon crystal panels can add a sense of fashion to the room; Installed on the ceiling, it can create a unique spatial atmosphere; Applied to furniture decoration, it can make furniture more beautiful and elegant. At the same time, the environmental performance of carbon crystal panels also provides a healthy living environment for people.

(4) In the field of electronic products

bamboo charcoal wall panel also have important applications in electronic product manufacturing. Due to its characteristics of conductivity, heat conduction, and anti-static, it is widely used in electronic products such as mobile phone screens and computer monitors. In terms of mobile phone screens, the high definition and good touch sensing performance of carbon crystal panels provide users with a better user experience; In computer monitors, the thermal conductivity of bamboo charcoal wall panel can effectively dissipate the heat generated by electronic components, ensuring the stable operation of the monitor.

(5) Other fields

bamboo charcoal wall panel can also be used in the manufacturing of artificial gemstones, medical devices, aerospace equipment, and other fields. In the production of artificial gemstones, the hardness and luster of bamboo charcoal wall panel make them an ideal material; In the field of medical devices, its excellent biocompatibility and antibacterial performance provide a new option for the manufacturing of medical devices; In terms of aerospace equipment, the lightweight, high strength, and high temperature resistance of bamboo charcoal wall panel can meet the strict requirements for materials in the aerospace field.

3、 Installation method of carbon crystal plate

(1) Preparation work

Preparation work is crucial before installing bamboo charcoal wall panel. Firstly, cleaning the walls and floors is a fundamental step, thoroughly removing dust, debris, etc. to ensure that the installation surface is clean and tidy. For uneven surfaces on walls and floors, careful inspection is necessary, and professional repair materials should be used to make them as smooth as possible. This step not only ensures the aesthetic appearance of the carbon crystal plate after installation, but also ensures the fit between the plate and the installation surface. In addition, the waterproof treatment of basic materials cannot be ignored. By applying waterproof coatings and other methods, moisture infiltration can be prevented to prevent the performance and service life of carbon crystal panels from being affected by humid environments.

(2) Measurement and cutting

Accurate measurement and cutting are key steps in the successful installation of bamboo charcoal wall panel. When conducting measurements, precise measuring tools should be used to ensure the accuracy of the dimensions. When cutting based on measurement results, special cutting tools such as professional carbon crystal cutting saws must be used. During the operation, it is necessary to strictly follow the correct method to avoid the breakage of the board due to improper operation. For example, when cutting, it is important to maintain a constant speed and avoid applying excessive force or suddenly changing the cutting direction. At the same time, pay attention to safety, wear protective equipment, and prevent accidental injuries.

(3) Installation process

After cutting is completed, enter the installation phase. Firstly, apply the glue evenly on the wall and floor. Choose high-quality glue to ensure it has good adhesion and durability. When applying glue, pay attention to uniform thickness to avoid situations where it is too thick or too thin locally. Then, place the bamboo charcoal wall panel on the bonding surface in order. During the placement process, handle with care to avoid collisions and scratches. Next, use specialized tools to flatten and squeeze the carbon crystal plate, ensuring a strong bond between the plate and the substrate. When installing, it is also necessary to pay attention to the combination of spacing and patterns. According to design requirements and personal preferences, different spacing distances and pattern combinations can be selected to achieve the best decoration effect. For example, equidistant spacing can be used to create a neat and orderly visual effect; You can also choose irregular intervals and patterned combinations to create a unique artistic atmosphere.

(4) Closing work

After the installation of the carbon crystal plate is completed, the finishing work is equally important. Perform joint filling treatment by using professional joint filling agents to fill the gaps between the boards, making the entire installation surface smoother and more aesthetically pleasing. The selection of grout should match the color and material of the carbon crystal plate to ensure a coordinated and consistent overall effect. After filling the joints, apply paint treatment. According to the decoration style and requirements, different colors and textures of paint can be selected to add a layer of protection and decoration to the carbon crystal panel. When painting, pay attention to applying evenly to avoid problems such as sagging and blistering. Finally, conduct a comprehensive inspection of the installed carbon crystal panel, remove irregular parts, and ensure that the decorative effect is complete and beautiful. If any defects or deficiencies are found, they should be repaired and adjusted in a timely manner. In short, the installation of bamboo charcoal wall panel needs to be strictly operated according to the process flow, paying attention to details and safety issues. Only in this way can the installation quality and durability be ensured, and the expected effect be achieved.

4、 Precautions for installation of carbon crystal plate

(1) Carbon Crystal Principle and Standards

Carbon crystal electric heating plate, also known as “carbon crystal electric low-temperature radiation heating system”. The heating principle is that under the action of an electric field, carbon molecule clusters in the heating element undergo molecular motion, resulting in intense friction and collision between carbon atoms. The heat generated is transmitted to the outside in the form of far-infrared radiation and convection, and the conversion rate between electrical energy and thermal energy is over 98%. The carbon crystal electric heating plate system fully utilizes the excellent flat heating characteristics of bamboo charcoal wall panel. During heating, the entire flat surface synchronously heats up, providing continuous heating and good thermal balance effect, overcoming the drawbacks of traditional heating products such as discontinuous heating and poor thermal balance effect.

The production of carbon crystal electric heating plates should comply with the GB/T 4654-2008 standard and pass the inspection of the National Infrared and Industrial Electric Heating Product Quality Supervision and Inspection Center, as well as the inspection of the relevant “General Requirements for Safety of Household and Similar Electrical Appliances” GB4706.1-2005 and “Special Requirements for Safety of Household and Similar Electrical Appliances Indoor Heaters” GB4706.23-2007 standards. The product has the characteristics of high insulation strength, flame retardancy, waterproofing, moisture resistance, and corrosion resistance.

(2) Installation requirements

When determining the number of carbon crystal electric heating plates to be installed, the insulation situation and area of the room should be considered. Houses that meet national energy-saving standards (with exterior wall insulation and double-layer glass) are generally equipped with a power output of 60-80 watts per square meter, which is 6-8 square meters of a 500 watt carbon crystal electric heating plate tube; Non energy-efficient residential buildings with poor insulation conditions (old houses, bungalows) are generally equipped with a power of 100-120 watts per square meter, which means a 500 watt carbon crystal electric heating plate tube of 4-5 square meters.

After determining the number of pieces, it is necessary to choose the location where the product can be installed, ensuring that there is appropriate space and power supply. The combination of each 500W carbon crystal electric heating plate is not recommended to exceed 4 pieces, and a temperature controller with a rated current of not less than 16 amperes should be connected; It is not recommended to use socket connections to reduce failure rates and hidden dangers; The branch power line of the renovated line should choose the national standard BV2.5 power line, and the main line should choose the national standard BV4.0 or above power line, and non-standard cables should not be used; Due to the long working hours of electric heating products and large voltage fluctuations in remote areas, it is recommended to choose a residual current switch with a rated current of 16A or above for the power switch; Electric heating facilities should have good grounding devices; The installation height of the thermostat should not be less than 1.3 meters, with a recommended height of 1.4 meters. The installation height of the carbon crystal panel on the wall should not be less than 1.2 meters.

(3) Points to note during the construction process

During the installation of carbon crystal panels, it is necessary to keep the construction site clean and avoid dust and other impurities that may affect the installation quality. At the same time, it is necessary to avoid collisions between the carbon crystal plate and sharp objects to prevent scratching the surface of the plate. After installation, timely maintenance and cleaning should be carried out, especially in areas that are prone to dirt and stains such as kitchens and bathrooms. Regular cleaning should be carried out to avoid bacterial growth.

Check the splicing parts and seal them properly to ensure a tight connection between the boards and prevent gaps from affecting the appearance and effectiveness of use. During the construction process, it is necessary to strictly follow the specifications to avoid installation quality problems caused by improper operation. For example, when applying glue, it is important to pay attention to uniform thickness and avoid situations where the glue is too thick or too thin locally; When placing bamboo charcoal wall panel, handle them gently to avoid collisions and scratches.

5、 Installation steps of carbon crystal plate underfloor heating system

(1) Preliminary preparation

Before installing the carbon crystal plate underfloor heating system, the ground must be thoroughly cleaned first. Clean up any debris, dust, etc. on the ground to ensure cleanliness. For uneven areas, use professional tools for grinding to make the ground as flat as possible. This step not only provides a solid foundation for subsequent installation work, but also ensures the installation quality and effectiveness of the carbon crystal plate underfloor heating system.

After completing the floor cleaning and grinding work, the next step is to lay a moisture-proof film. The function of moisture-proof film is crucial, as it can prevent moisture inside the house and prevent damage to the carbon crystal floor heating system caused by moisture. Meanwhile, the moisture-proof film can also protect the installation materials from damage, ensuring the stability and durability of the system.

At the same time as laying the moisture-proof film, it is also necessary to determine the materials and tools required for installation. The installation materials for carbon crystal panel underfloor heating systems mainly include insulation panels, reflective films, carbon crystal heating chips, steel wire mesh, PVC pipes, etc. In terms of tools, it is necessary to prepare cutting tools, laying tools, connecting tools, etc. Ensure the completeness of materials and tools to provide assurance for the smooth progress of installation work.

(2) Laying sequence

Firstly, lay the insulation board, reflective film, and carbon crystal heating chip in sequence. The laying of insulation boards should adopt a full laying method, which can minimize heat loss, improve the efficiency of ground heating, and also achieve insulation effect. In addition to covering the entire floor, insulation boards like baseboards should also be installed at the corners of the walls to achieve comprehensive insulation.

The reflective film is laid on top of the insulation board, which can also have the effect of insulation. It can retain indoor heat as much as possible without causing heat loss.

After laying the insulation board and reflective film, cut the groove line. According to the design requirements, accurately cut the groove line to prepare for placing PVC pipes and digging docking holes.

After placing the PVC pipes and digging the docking holes, lay reinforced steel wire mesh on top. Steel wire mesh can ensure that the carbon crystal heating plate will not be damaged under heavy pressure, extending the service life of the carbon crystal heating plate. At the same time, attention should be paid to the flatness and firmness of the laying to ensure that the steel wire mesh can play its due role.

Finally, bury the ground wire. The burial of ground wires should comply with relevant standards and specifications to ensure the safety and stability of the system.

(3) Closing work

Lay the floor on the underfloor heating system and complete the installation of the entire carbon crystal panel underfloor heating system. When choosing flooring, factors such as thermal conductivity and environmental performance should be considered to ensure compatibility with carbon crystal floor heating systems.

It should be noted that the installation cost of carbon crystal panel underfloor heating system varies depending on the choice. Generally speaking, installation costs mainly include material costs, construction costs, and machinery usage costs. In terms of material costs, the price of carbon crystal heating plates is calculated per square meter. If the room area is relatively large, the number of carbon crystal heating plates that need to be installed will increase, and the cost will also increase accordingly. In addition, the quality and price of materials such as insulation panels, reflective films, and steel wire mesh will also affect installation costs. The construction cost needs to be calculated according to the local labor price, and the construction cost may vary in different regions. The cost of mechanical use is also a part of the installation cost, usually calculated per square meter. Together with the construction cost, it constitutes the overall cost of installing the carbon crystal panel underfloor heating system.

Meanwhile, the prices of carbon crystal panel underfloor heating systems of different brands and qualities will also vary. Consumers should consider various factors and choose cost-effective products and installation plans based on their actual needs and budget when choosing carbon crystal panel underfloor heating systems.

6、 Carbon Crystal Plate Installation Cases and Lessons Learned

(1) Time issue

During the installation process of bamboo charcoal wall panel, many cases have shown that time may not necessarily be fast. For example, some consumers originally expected to complete the decoration in a short period of time, but the actual situation is quite different. Some consumers are promised to complete the contract within a certain number of days, but after paying, the time is completely beyond their control. For example, some consumers were originally told that it would only take 3 days or two weeks to complete the whole house quick installation, but in actual operation, due to various reasons, the construction period was greatly extended, and there was a significant gap between the promised time. This may be due to delayed material supply, unreasonable arrangement of construction personnel, and other reasons.

(2) Environmental issues

bamboo charcoal wall panel themselves may not have significant environmental issues, but the installation process may pose environmental hazards. Some consumers have reported that installing carbon crystal panels requires a large amount of foam adhesive and structural adhesive, and all adhesive products must contain formaldehyde. For example, in some cases of whole house customization, in order to fix the carbon crystal panel to the wall, a large amount of glue needs to be applied between the carbon crystal panel and the bottom plate, which increases the indoor formaldehyde content and poses a potential threat to human health.

(3) Cost issue

The installation cost of bamboo charcoal wall panel is often higher than expected. The price of “carbon crystal board” itself may be between 50-60 yuan per square meter, but with the addition of lines, edge banding, shipping and upstairs handling fees of 8 yuan per square meter, as well as the cost of using European pine board or nine centimeter board as the base, the labor cost for the base alone is 60 yuan per square meter. Each European pine board or nine centimeter board is about 35-50 yuan per square meter, and there are also auxiliary materials such as wooden blocks and nails that cost 10 yuan per square meter. In this way, the actual cost per square meter for completing the construction of the “carbon crystal board” is at least 168 yuan. In addition, various additional costs may arise during the actual installation process. For example, some consumers are required to pay material transportation fees, installation fees, etc. when installing carbon crystal panels, and what was originally thought to be a low-priced decoration eventually becomes a high cost. For example, some consumers are constantly charged prices by businesses under various pretexts during the whole house renovation of carbon crystal panels, ultimately spending far beyond their budget.

These practical cases remind us to be cautious when choosing carbon crystal plate installation. It is important to carefully understand whether the promises made by the merchant are true and reliable. Before signing the contract, it is necessary to carefully review the contract terms, clarify the various expenses and construction period, and avoid being deceived. At the same time, we should pay attention to environmental issues, choose environmentally friendly installation methods and materials, and ensure the health and safety of the living environment.

Leave A Comment