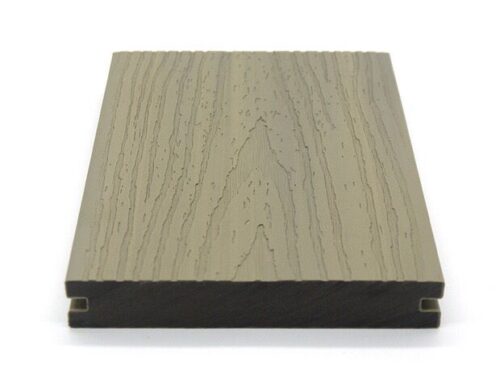

Outdoor wood-plastic composite (WPC) products are becoming more and more popular due to their combination of

aesthetics and durability. These products are usually made of a mixture of wood fiber/wood flour, polyethylene

(PE) and various additives. The proportion of PE in the mixture can significantly affect the properties and

properties of the final product. In this article, we will explore how different percentages of PE affect outdoor

WPC products.

Understand composition

WPC products consist of the following materials:

Wood fiber/wood flour: provides a natural look and texture.

Polyethylene (PE) : acts as an adhesive and imparts strength and flexibility.

Additive: enhances specific properties, such as UV resistance, color stability, and processing efficiency.

The proportions of these components can be adjusted to obtain different performance characteristics. Let’s further

study the effects of different PE content.

PE content was low (20-30%)

WPC products with lower PE content tend to have higher wood content, which gives them a more natural look and

feel. However, there are trade-offs:

Pros:

Natural appearance: the higher wood content enhances the natural appearance, making it closer to traditional wood

products.

Enhanced texture: these products usually have a better touch, which is ideal for applications such as decoration

and cladding.

Cons:

Low durability: PE content reduction will lead to moisture, decay and insect resistance reduced.

Brittleness: products may be more brittle, prone to rupture or fracture under pressure.

Higher Maintenance: increased wood content may require more maintenance to keep the product looking good over

time.

Moderate PE content (30-50%)

It is a balanced combination that offers a trade-off between the natural appearance of wood and the durability of

plastic.

Pros:

Balanced features: provides a good balance between natural beauty and improved durability.

Increased Strength: higher PE content can enhance the structural integrity and impact resistance of the product.

Moderate Maintenance: products with low PE content require less maintenance while still retaining some natural

wood properties.

Cons:

Texture compromise: while better than high PE content products, the texture may not be as natural as low PE

content WPC.

Cost considerations: due to increased plastic use, products with moderate PE content may be more expensive than

those with high wood content.

High Pe content (50-70%)

The WPC products with high PE content are mainly plastics, which have obvious advantages and disadvantages.

Pros:

High durability: excellent moisture, corrosion and pest resistance, very suitable for harsh outdoor environment.

Flexibility and strength: greater flexibility reduces the risk of cracking and improves impact resistance.

Low maintenance cost: requires minimal maintenance and is easy to clean and can maintain its appearance over time.

Cons:

The appearance is not natural: a high plastic content makes the product look less like natural wood.

Increased cost: as the use of plastic resins increases, higher PE content usually means higher costs.

Heat Preservation: these products may retain more heat, making them less comfortable to walk barefoot in hot

climates.

Choose the right balance

The choice of PE content in WPC products ultimately depends on the intended application and desired performance.

For applications where the appearance of natural wood is critical, lower PE content may be preferred. On the other

hand, for areas exposed to severe weather conditions or frequent use, higher PE content will provide the necessary

durability and low maintenance advantages.

In summary, changing the percentage of polyethylene in outdoor WPC products significantly affects their

performance, aesthetics, and maintenance requirements. By understanding these differences, manufacturers and

consumers can make informed decisions and choose WPC products that suit their specific needs.

Starstone ensures that our outdoor wood and plastic products are made from the best balance of wood.

Leave A Comment