1. Material selection

Wood-plastic decking production began with the careful selection of raw materials. Typically, this involves recycling mixtures of wood fibers and plastic polymers. Wood fibers can come from sawdust, wood chips, and even agricultural byproducts, while plastics usually come from recycled polyethylene or polypropylene.

2. Mix and match

Once the raw materials are collected, they are thoroughly mixed and compounded. This step involves heating the plastic until it melts and then binding it to wood fibers. Mix the mixture to ensure consistency and uniformity of material. Additives such as UV stabilizers, colorants and adhesives are also included to enhance the performance and appearance of the final product.

3.Extrusion process

The mixed material is then fed into an extruder, which forms the material into the desired profile. The extrusion process includes pushing the heated mixture into the mold to form a continuous-shaped decorative plate. Extruders can create a variety of contours and textures to mimic the appearance of natural wood while providing superior durability.

4. Cool and cut

When the panels leave the extruder, they are cooled with water or air to solidify their shape. The cooled plate is then cut to the desired length. This step ensures the uniformity of the plate and prepares it for the next stage of finishing and quality control.

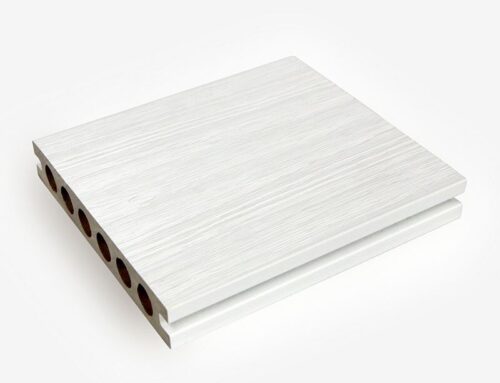

5. Surface treatment

In order to enhance the appearance and performance of WPC decking , surface treatment can be carried out. This can include embossing, sanding or brushing your teeth to create a wood-like texture. In addition, protective coatings or sealants can be added to improve resistance to moisture, UV light and stains.

6. Quality control

Quality control is an important aspect of wood-plastic deck production. Each panel is rigorously tested to ensure that it meets industry standards for strength, durability and appearance. Defective boards are identified and removed to maintain high product quality.

7. Packaging and distribution

Finally, finished wood-plastic flooring is packaged and ready for distribution. They are carefully packed to prevent damage during transport and storage. From here, panels are shipped to distributors, retailers, and eventually to customers who enjoy the benefits.

The production of WPC decking is a meticulous process that combines advanced technology with sustainable practices. By utilizing recycled materials and innovative manufacturing technologies, WPC decking provides a durable, eco-friendly alternative to traditional wood decking, ideal for enhancing outdoor spaces with minimal maintenance.

Leave A Comment