Judging the quality of Wood Plastic Composite (WPC) products involves evaluating several factors related to their materials, manufacturing process, and performance characteristics. Here’s a detailed guide on how to assess the quality of WPC products:

—

- Material Composition

The quality of WPC products heavily depends on the ratio and type of raw materials used, which typically include wood fibers, plastic, and additives.

– Wood-to-Plastic Ratio: A good-quality WPC product generally has a balanced ratio of wood fibers (or other natural fibers) to plastic. A typical range is 50-70% wood fibers and 30-50% plastic. A higher wood content usually gives the material a more natural look, but too much wood can reduce moisture resistance. Look for products with the right balance.

– Type of Plastic: The type of plastic used matters. HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) are common plastics in WPC products. HDPE-based WPC is more flexible and eco-friendly, while PVC-based WPC is more rigid and durable.

– Additives: High-quality WPC includes stabilizers, UV inhibitors, and anti-fungal additives. These additives help improve the product’s resistance to UV rays, moisture, insects, and mildew.

—

- Surface Finish and Texture

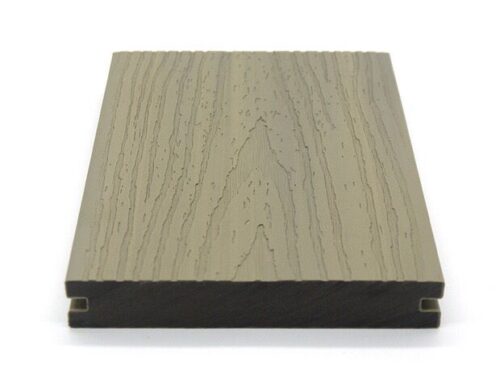

– Smoothness: Inspect the surface for a smooth, even texture. Poor-quality WPC may have rough or inconsistent surfaces due to poor manufacturing.

– Wood Grain Appearance: For WPC products that mimic wood, look at how well the grain pattern replicates natural wood. High-quality WPC products will have a detailed, authentic wood grain appearance, while lower-quality products may look artificial or have shallow, less-defined patterns.

– Uniform Color: A high-quality WPC product should have a uniform, rich color throughout the board or panel. Inconsistent or faded colors may indicate poor pigmentation or UV resistance.

—

- Density and Weight

– Weight: Heavier WPC boards are generally more durable and have a higher wood fiber content, which contributes to the overall strength. If the WPC material feels unusually light, it may be less dense, which could impact its durability and strength.

– Density: High-density WPC products are stronger, more impact-resistant, and less prone to warping or bending. A simple test is to try slightly pressing your fingernail into the surface; high-quality WPC should resist denting or deformation.

—

- Durability and Strength

– Impact Resistance: Good WPC should resist impacts and not easily crack or break under moderate force. High-quality WPC will have a high tensile strength, meaning it can handle weight and pressure without bending or cracking.

– Scratch and Abrasion Resistance: Quality WPC products should have a surface that resists scratches and abrasion, especially in high-traffic areas. Some WPC materials come with a capped layer, which is a protective coating that provides extra scratch resistance.

—

- Water and Moisture Resistance

One of the key benefits of WPC is its resistance to moisture, but the level of moisture resistance can vary between products.

– Water Absorption Rate: High-quality WPC products have very low water absorption rates (typically less than 1%). Check with the manufacturer for the absorption rate of the product.

– Edge Swelling: Poor-quality WPC can absorb water through exposed edges, leading to swelling, warping, or delamination over time. Inspect samples or ask for product test results showing how the material performs in wet conditions.

—

- UV Resistance

Since many WPC products are used outdoors, their ability to withstand UV radiation is crucial for maintaining appearance and durability.

– Fade Resistance: High-quality WPC products should be UV-resistant to prevent color fading or surface degradation due to prolonged exposure to sunlight. Look for products with UV inhibitors that slow down the fading process. Lower-quality WPC will fade more quickly.

– Warranty: A long-term UV resistance warranty (typically 15–25 years) from the manufacturer can indicate the product’s durability against fading and cracking.

—

- Manufacturing Quality and Consistency

– Precision of Cuts and Edges: Inspect the edges and cuts of the WPC product. High-quality WPC should have clean, sharp edges without rough spots or splintering. If cuts are uneven or show signs of poor molding, this may indicate lower manufacturing standards.

– Consistency Between Boards: If you’re dealing with multiple boards or panels, check for consistency in size, shape, and finish. Lower-quality WPC products may vary in thickness, length, or texture, leading to installation difficulties.

—

- Fire Resistance

Some high-quality WPC products come with fire-resistant additives. If fire resistance is important for your application, check whether the product meets specific fire rating standards like Class A or B for building materials. Poor-quality WPC may lack this level of protection.

—

- Eco-Friendliness and Sustainability

– Recycled Content: WPC products made from recycled wood fibers and plastics are more eco-friendly. Look for certifications like FSC (Forest Stewardship Council) for sustainable wood and recycled plastic percentages. A higher proportion of recycled materials is usually a good indicator of environmentally friendly practices.

– Certifications: Certifications such as ISO 9001 (for quality management) and ISO 14001 (for environmental management) are positive signs of a manufacturer’s commitment to producing high-quality, sustainable products.

—

- Warranty and Manufacturer Reputation

– Warranty Length: High-quality WPC products generally come with longer warranties, typically ranging from 10 to 25 years, covering issues like fading, cracking, warping, and structural integrity. Compare warranties from different manufacturers to gauge their confidence in the product.

– Reputation: Research the manufacturer or supplier to determine their reputation for quality. Brands with good track records and positive customer reviews are more likely to offer durable, high-quality WPC products.

—

- Installation and Maintenance

– Ease of Installation: High-quality WPC products should be easy to install, with consistent dimensions that allow for smooth alignment and attachment. Some products may come with interlocking systems, making installation more efficient.

– Maintenance Requirements: Low-maintenance WPC products that require minimal cleaning or treatments indicate higher quality. They should not need frequent sealing, painting, or heavy-duty maintenance like natural wood.

—

- Price vs. Quality

While cost can be a factor in determining quality, the cheapest WPC products may use inferior materials and manufacturing processes. Conversely, the most expensive options don’t always guarantee the highest quality. Compare price-to-quality ratios by considering all of the factors above, rather than focusing solely on price.

—

Summary of Key Indicators for Judging WPC Quality:

- Material Composition: Balanced wood-to-plastic ratio and quality additives.

- Surface Finish: Smooth, uniform texture and realistic wood grain.

- Density and Weight: Heavier, denser boards usually indicate better quality.

- Durability: High impact and scratch resistance.

- Moisture Resistance: Low water absorption and resistance to edge swelling.

- UV Resistance: Fade-resistant materials with UV inhibitors.

- Manufacturing Consistency: Precision-cut edges and uniformity between boards.

- Fire Resistance: Look for fire ratings like Class A or B.

- Eco-Friendliness: High percentage of recycled content and relevant certifications.

- Warranty: Longer warranties indicate greater manufacturer confidence.

- Ease of Installation: Consistent dimensions for easier installation.

- Price-to-Quality: Balance cost with material performance and durability.

By evaluating these factors, you can better assess the quality of a WPC product and make an informed purchase decision.

Leave A Comment