Judging the quality of a WPC (Wood Plastic Composite) ceiling involves evaluating several key factors that can affect its durability, appearance, and overall performance. Here are some guidelines to help you assess the quality of WPC ceilings:

- Material Composition

– WPC Ratio: Look for products with a balanced composition of wood fibers and plastic. A good WPC ceiling typically contains 60-70% wood fibers and 30-40% plastic. Higher wood content often enhances aesthetic appeal and reduces environmental impact.

– Type of Plastic Used: Check if the ceiling uses high-density polyethylene (HDPE) or polyvinyl chloride (PVC). HDPE is generally more durable and resistant to moisture compared to PVC.

- Manufacturing Process

– Extrusion Quality: Quality WPC ceilings are produced using advanced extrusion methods that ensure uniform density and a consistent finish. Inconsistent thickness or visible flaws in the material can indicate poor manufacturing.

– Certifications: Look for products that meet industry standards and certifications (such as CE, ASTM, or ISO) which indicate adherence to quality control processes.

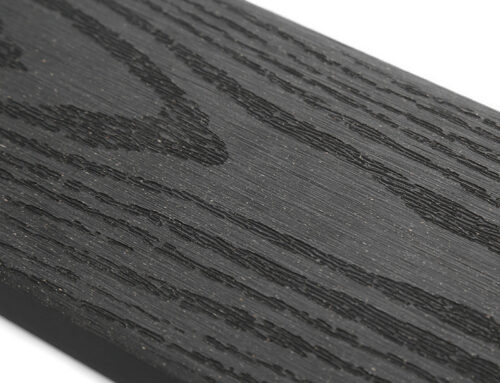

- Surface Finish and Aesthetics

– Surface Texture: A high-quality WPC ceiling should have a smooth, even surface with a consistent texture. Check for any rough spots, imperfections, or inconsistencies that might affect appearance and performance.

– Color Consistency: Examine the color and finish for uniformity. Quality panels will have consistent coloration throughout, without noticeable discoloration or fading.

- Durability and Performance

– Moisture Resistance: High-quality WPC should be resistant to moisture and not easily warped or damaged by humidity. Look for products that specify moisture resistance or waterproof qualities.

– UV Resistance: Check if the panels are treated for UV resistance, which helps prevent fading and degradation when exposed to sunlight, especially for outdoor installations.

– Impact Resistance: Good WPC ceilings should have a level of impact resistance that prevents cracking or denting. Some manufacturers provide specifications regarding impact resistance ratings.

- Fire Resistance

– Fire Ratings: Investigate if the WPC ceiling has any fire resistance ratings or certifications. Panels that are classified as fire-resistant can enhance safety in residential and commercial settings.

- Weight and Thickness

– Panel Thickness: Thicker panels often indicate better quality as they are more durable and provide better insulation. A typical thickness ranges from 6mm to 20mm.

– Weight: A heavier panel may indicate a denser material, which is usually a sign of better quality. However, ensure the weight is appropriate for the intended installation.

- Warranty and Customer Support

– Warranty Duration: Check the warranty offered by the manufacturer. A longer warranty period usually indicates confidence in product durability and quality.

– Customer Service: Evaluate the manufacturer’s customer support. Reliable manufacturers should provide clear guidance, installation support, and responsive customer service.

- User Reviews and Recommendations

– Research Reviews: Look for customer reviews and ratings online to gauge user satisfaction and experience with the WPC ceiling product.

– Seek Recommendations: Ask professionals in the construction or renovation industry for recommendations on high-quality WPC brands.

- Cost Consideration

– Price vs. Quality: While lower-priced options may be tempting, extremely low prices can indicate lower quality. Balance cost with the quality attributes mentioned above to make an informed choice.

- Sample Testing

– Request Samples: If possible, request samples from the manufacturer or supplier to examine the material firsthand. This allows you to assess its texture, weight, and overall quality before making a purchase.

By considering these factors, you can better judge the quality of a WPC ceiling and choose a product that meets your aesthetic and functional needs.

Leave A Comment