1.How to install wood plastic flooring correctly?

Installing wood-plastic composite (WPC) flooring requires some specific steps to ensure a successful and lasting result. Here’s a guide to help you install it properly:

### Materials and Tools Needed

– WPC flooring planks

– Underlayment (if required)

– Measuring tape

– Pencil or chalk

– Spacers

– Rubber mallet

– Circular saw or flooring cutter

– Tapping block

– Utility knife

– Safety goggles

### Step-by-Step Installation Guide

#### 1. **Acclimate the Flooring**

– **Condition the Planks**: Allow the WPC flooring planks to acclimate in the room where they will be installed for at least 48 hours. This helps the material adjust to the room’s temperature and humidity.

#### 2. **Prepare the Subfloor**

– **Clean the Subfloor**: Ensure the subfloor is clean, dry, and free of any debris. Any uneven spots should be leveled out.

– **Check for Moisture**: Make sure the subfloor has no moisture issues to prevent damage.

– **Install Underlayment (if needed)**: Some WPC flooring comes with pre-attached underlayment, but if yours doesn’t, lay down an underlayment according to the manufacturer’s guidelines.

#### 3. **Plan Your Layout**

– **Measure and Plan**: Measure the room and plan the layout of the planks so that the cuts at the edges are evenly distributed.

– **Stagger the Planks**: Ensure that the joints between planks are staggered by at least 6–8 inches to create a natural look and maintain the strength of the flooring.

#### 4. **Install the First Row**

– **Lay the First Plank**: Start in the corner of the room with the groove side of the plank facing the wall.

– **Place Spacers**: Use spacers between the planks and the wall to leave an expansion gap (typically ¼ inch) that allows the flooring to expand and contract.

– **Connect Planks**: Place the next plank end-to-end and connect by angling the tongue side into the groove of the previous plank, pressing down to click them together.

#### 5. **Continue Laying the Planks**

– **Repeat the Process**: Continue laying the planks, using the tapping block and rubber mallet as needed to ensure a tight fit. Make sure the expansion gaps remain intact.

– **Cut the Last Plank of Each Row**: Use a circular saw or utility knife to cut the last plank to fit, leaving the expansion gap.

#### 6. **Stagger and Complete the Installation**

– **Stagger the Seams**: Begin the next row with a plank that is cut to a different length to maintain the staggered pattern.

– **Join Rows**: Attach the second row by inserting the tongue into the groove of the first row at an angle and lowering it into place. Use the tapping block and rubber mallet to secure the planks.

#### 7. **Finish Up**

– **Install the Final Row**: Measure and cut the planks lengthwise if necessary, ensuring an expansion gap remains.

– **Remove Spacers**: Once the flooring is complete, remove all spacers from around the perimeter.

– **Install Baseboards and Trim**: Cover the expansion gap with baseboards or trim without attaching it directly to the flooring to allow for movement.

### Tips for Success

– **Safety First**: Always wear safety goggles when cutting planks.

– **Avoid Tight Fitting**: Do not force planks together too tightly, as this could damage the locking mechanism.

– **Keep It Clean**: Clean as you go to avoid debris from interfering with the installation.

This method ensures that your wood-plastic composite flooring is installed properly, providing a durable and attractive finish.

2.What tools and materials are needed to install wood plastic flooring?

To install wood plastic composite (WPC) flooring, you’ll need specific tools and materials to ensure a smooth and successful process. Here’s a list of what you’ll need:

### Tools Required

1. **Measuring Tape**: To accurately measure the dimensions of the room and the planks.

2. **Pencil or Chalk**: For marking cuts and measurements on the planks.

3. **Spacers**: To maintain expansion gaps between the flooring and the wall.

4. **Rubber Mallet**: To gently tap the planks into place without damaging them.

5. **Tapping Block**: To protect the edges of the planks while securing them together.

6. **Circular Saw or Flooring Cutter**: For cutting planks to fit along the walls and around obstacles.

7. **Jigsaw**: Useful for more detailed cuts around corners or irregular spaces.

8. **Utility Knife**: For trimming underlayment or cutting planks as needed.

9. **Level**: To ensure the subfloor is even before laying the planks.

10. **Safety Goggles**: To protect your eyes while cutting or trimming materials.

11. **Knee Pads**: For comfort when working on your knees for long periods.

### Materials Needed

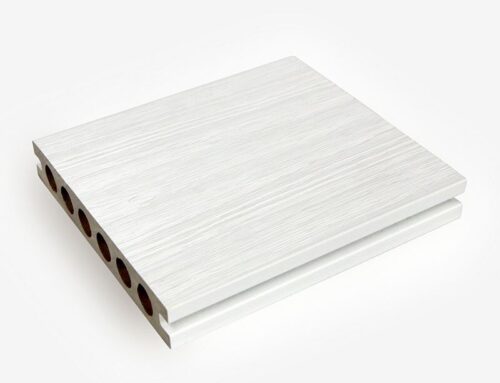

1. **WPC Flooring Planks**: Choose high-quality planks that match your desired look and fit your budget.

2. **Underlayment** (if needed): Some WPC flooring comes with pre-attached underlayment, but if not, you’ll need to install a separate underlayment to provide cushioning and sound absorption.

3. **Moisture Barrier**: Necessary for installations over concrete or moisture-prone subfloors.

4. **Adhesive Tape**: To secure the underlayment, if required.

5. **Baseboards or Molding**: To cover the expansion gaps around the edges once the flooring is installed.

6. **Transition Strips**: To provide a smooth transition between the new flooring and adjacent surfaces.

### Optional Items

– **Wood Filler**: To fill in any gaps or imperfections.

– **Clamps**: Helpful for holding planks in place during installation.

– **Vacuum or Broom**: To clean the subfloor and keep debris out of the installation area.

Having these tools and materials ready will help ensure that your installation process is efficient and that the finished floor looks professional and long-lasting.

3.Whether the plastic wood floor need professional installation?

Whether you need professional installation for wood plastic composite (WPC) flooring depends on several factors, including your level of experience, the type of flooring, and the complexity of the space. Here are some considerations to help you decide:

### When Professional Installation is Recommended

1. **Complex Room Layouts**: If the room has many corners, odd angles, or obstacles like pillars and doorways, a professional installer can ensure precise cutting and fitting.

2. **Lack of Experience**: If you have little or no DIY experience, hiring a professional can help prevent mistakes that might lead to costly repairs.

3. **Large Areas**: Installing flooring in a large space can be time-consuming and require specialized knowledge for seamless transitions and proper alignment.

4. **Time Constraints**: If you need the project completed quickly, a professional will likely be more efficient.

### When DIY Installation is Feasible

1. **Simple Room Layouts**: If the room is rectangular or has a straightforward layout, DIY installation is more manageable.

2. **Basic DIY Skills**: If you have prior experience with home improvement projects, WPC flooring is designed to be user-friendly, often featuring click-lock systems that don’t require glue or nails.

3. **Proper Tools and Preparation**: With the right tools and materials (listed above), a DIY installation is achievable.

4. **Step-by-Step Instructions**: Many WPC flooring products come with detailed instructions, making the process more accessible for non-professionals.

### Benefits of DIY Installation

– **Cost Savings**: You save on labor costs.

– **Personal Satisfaction**: Completing a project yourself can be rewarding.

– **Flexibility**: You can work at your own pace.

### Benefits of Professional Installation

– **Expert Precision**: Ensures a high-quality finish with fewer mistakes.

– **Warranty**: Some flooring warranties require professional installation to remain valid.

– **Time Efficiency**: The job can be done more quickly by a trained installer.

Conclusion

If you’re comfortable with basic DIY tasks and have the necessary tools and time, you can install WPC flooring yourself, especially in simpler spaces. However, if you prefer a guaranteed, high-quality outcome or face a challenging space, professional installation is a worthwhile investment.

4.Wood plastic floor daily how to clean and maintain?

Cleaning and maintaining wood plastic composite (WPC) flooring daily helps preserve its appearance and extend its lifespan. Here’s a comprehensive guide on how to care for WPC flooring:

### Daily Cleaning Routine

1. **Sweep or Vacuum**:

– **Sweep with a Soft Broom**: Use a soft-bristled broom to remove dust, dirt, and debris.

– **Vacuum with a Hard Floor Attachment**: Avoid using a beater bar, as this could scratch or damage the floor’s surface.

2. **Dry Mop**:

– Use a microfiber mop for quick touch-ups to collect fine dust and keep the floor looking clean and shiny.

### Weekly Cleaning

1. **Damp Mopping**:

– **Use a Damp Mop**: Lightly dampen a microfiber mop with water. Avoid soaking the mop or allowing excess water to sit on the floor, as standing water can cause damage over time.

– **Mild Cleaning Solution**: If needed, use a diluted, pH-neutral cleaner specifically designed for WPC or vinyl flooring. Avoid harsh chemicals or abrasive cleaners that could damage the surface.

2. **Spot Cleaning**:

– For spills or stains, wipe up immediately with a soft cloth and a small amount of water or a mild cleaner. Avoid leaving liquids on the floor for an extended period.

### Long-Term Maintenance Tips

1. **Avoid Excessive Water**:

– **No Wet Mopping**: Excessive water can penetrate the seams and damage the core of the planks. Always use a slightly damp mop rather than a soaking one.

2. **Protect from Scratches**:

– **Use Furniture Pads**: Place felt pads or protective covers under the legs of furniture to prevent scratches.

– **Use Rugs or Mats**: Place mats at entrances to trap dirt and grit that could scratch the surface. Avoid using rubber-backed mats, as they may discolor the flooring.

3. **Avoid Abrasive Tools**:

– Never use steel wool, scouring pads, or stiff-bristled brushes. These can scratch and damage the surface of WPC flooring.

4. **Protect from Sunlight**:

– Use curtains or blinds to limit direct sunlight, as UV rays can cause discoloration over time. You can also use UV-protective window film to help prevent fading.

### Tips for Keeping WPC Flooring in Top Shape

– **Quick Cleanup**: Wipe up spills as soon as possible to avoid staining or water damage.

– **Avoid Dragging**: Lift furniture instead of dragging it across the floor to prevent scratches.

– **Regular Inspection**: Periodically check for signs of wear or damage and address any issues promptly to prevent them from worsening.

### What to Avoid

– **Harsh Chemicals**: Avoid using bleach, ammonia, or any acidic cleaning products.

– **Steam Mops**: High heat and moisture can compromise the integrity of WPC flooring over time.

– **Polish or Wax**: These products are not needed and can leave a residue or cause build-up.

By following these daily and long-term maintenance tips, you can keep your wood plastic flooring looking beautiful and extend its life.

5.Whether need special maintenance plastic wood floor?

Wood plastic composite (WPC) flooring does not require special or intensive maintenance compared to traditional hardwood or other flooring types. However, adhering to some specific care practices can help maintain its quality and appearance for years. Here are some considerations to determine whether special maintenance is needed:

### General Maintenance Requirements

1. **Routine Cleaning**:

– **Daily Sweeping or Vacuuming**: Basic cleaning with a soft broom or a vacuum (with a hard floor attachment) helps remove dust and debris.

– **Damp Mopping**: Occasional damp mopping with a mild, pH-neutral cleaner helps maintain the floor’s cleanliness without damaging its surface.

2. **Avoiding Harsh Treatments**:

– **No Waxing or Polishing**: Unlike traditional hardwood, WPC flooring doesn’t need waxing or polishing to maintain its shine.

– **Non-Abrasive Cleaners**: Harsh chemicals and abrasive tools should be avoided as they can damage the protective layer of the flooring.

### Protective Measures

1. **Furniture Pads**:

– Placing felt pads or protective covers under furniture legs helps prevent scratches.

2. **Area Rugs and Mats**:

– Using rugs or mats in high-traffic areas can reduce wear and tear, but make sure they are not rubber-backed, as these can discolor the floor.

3. **Avoiding Excess Water**:

– WPC flooring is more water-resistant than many other types, but it’s still wise to avoid pooling or standing water for prolonged periods to protect the seams and core.

### Special Maintenance Situations

1. **Sunlight Protection**:

– Prolonged exposure to direct sunlight may cause discoloration over time. Use curtains, blinds, or UV-blocking window film to protect the floor in rooms with heavy sunlight.

2. **Scratch Prevention**:

– For homes with pets, keeping their nails trimmed and using mats in areas they frequent can prevent surface scratches.

3. **Heavy Furniture and Appliances**:

– Use furniture sliders or lift heavy items when moving them to avoid scratching or denting the floor.

### Special Cleaning for Stubborn Stains

– **Spot Cleaning**: For stubborn stains, a soft cloth with a small amount of diluted pH-neutral cleaner or specialized WPC cleaner can help.

– **No Steam Cleaning**: Steam mops or steam cleaners should be avoided as the high heat and moisture may damage the flooring over time.

Conclusion

While WPC flooring does not require *special* maintenance in the sense of unique or demanding care routines, it does benefit from mindful practices. Regular cleaning, avoiding harsh products, and using protective measures like furniture pads and rugs are generally enough. The ease of maintenance is one of the reasons why WPC flooring is popular—it combines durability with simple care needs.

6.Plastic Wood floor after long-term use, how to carry out renovation or repair?

Renovating or repairing wood plastic composite (WPC) flooring after long-term use can help restore its appearance and functionality. Here’s how you can carry out both minor repairs and more significant renovations:

### 1. **Inspect the Damage**

– **Assess the Condition**: Check for common issues like scratches, dents, loose planks, or warping.

– **Determine Repair Needs**: Decide whether you need to replace a few planks, fix minor surface damage, or undertake a more extensive renovation.

### 2. **Repairing Minor Scratches and Scuffs**

– **Use a Repair Kit**: Purchase a WPC flooring repair kit that matches the color of your floor. These kits often come with touch-up markers, wax sticks, or putty for filling minor scratches.

– **Apply and Blend**: Follow the kit’s instructions to fill the scratches and blend them with the surrounding floor. Smooth the area with a soft cloth after the filler has set.

– **Protect the Surface**: Apply a clear sealer if recommended by the repair kit manufacturer to add a layer of protection.

### 3. **Replacing Damaged Planks**

– **Identify the Planks**: If specific planks are damaged beyond repair, mark and remove them carefully.

– **Remove the Damaged Plank**:

– **Click-Lock Planks**: Disconnect and lift the planks starting from the wall nearest to the damaged plank and work toward it. Replace the damaged piece, and reinstall the surrounding planks.

– **Glued or Secured Planks**: Use a utility knife to cut around the plank, and gently lift it out. Clean the area and remove any adhesive residue before inserting a new plank.

– **Install the New Plank**: Fit the new plank into the space, ensuring it aligns properly with the rest of the floor. For click-lock systems, lock the new piece in place. If adhesive is needed, apply it to secure the plank.

– **Finishing Touches**: Press the plank down firmly and use a tapping block if necessary to ensure it sits flush with the rest of the floor.

### 4. **Fixing Loose or Squeaky Planks**

– **Secure the Plank**: For loose or squeaky planks, check the locking system or adhesive. Apply a small amount of wood glue under the plank edge and press down firmly to secure it. Weigh it down with a heavy object until the adhesive dries.

– **Use a Lubricant**: If squeaking persists, use a lubricant like powdered graphite or talcum powder in the seams to reduce friction.

### 5. **Refinishing the Surface**

– **Surface Wear and Fading**: Unlike traditional wood floors, WPC floors typically cannot be sanded and refinished. However, you can use a specially formulated WPC floor polish to restore shine and mask minor surface imperfections.

– **Reapply Protective Coating**: Apply a floor finish or sealer designed for WPC or vinyl floors to enhance protection and improve the appearance. Follow manufacturer guidelines for best results.

### 6. **Deep Cleaning Before Renovation**

– **Deep Clean**: Before performing any repair or renovation, clean the floor thoroughly with a mild, pH-neutral cleaner and a damp mop to remove dirt and grime.

– **Dry the Floor**: Ensure the floor is completely dry before beginning repairs or applying any products.

### 7. **Professional Help**

– **Severe Damage**: If your WPC floor has significant damage such as widespread warping or deep gouges, it might be best to seek professional help for assessment and repair.

– **Warranty Considerations**: Check the flooring warranty before performing major repairs or replacements to avoid voiding any coverage.

### Maintenance After Renovation

– **Routine Care**: Continue daily and weekly cleaning to keep the floor in good condition.

– **Protective Measures**: Use area rugs and furniture pads to prevent new damage and reduce wear in high-traffic areas.

By following these steps, you can restore and maintain your WPC flooring, extending its life and keeping it looking great.

Leave A Comment