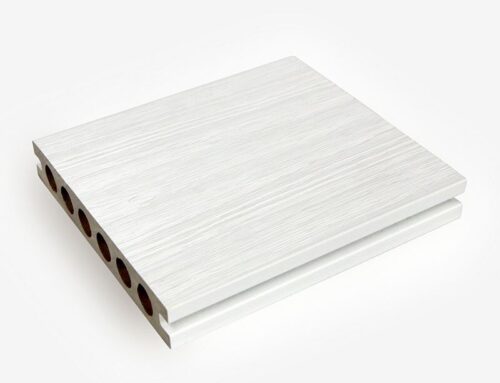

Wood-plastic composite (WPC) decking is popular as a durable and environmentally friendly alternative to traditional wood decking. However, concerns about the presence of formaldehyde in building materials often raise questions about the safety and environmental impact of wood-plastic decking. This paper aims at a comprehensive overview of wood-plastic decking in the formaldehyde, described its sources, regulations and safety measures.

What is formaldehyde?

Formaldehyde is a colorless, strong-smelling gas, commonly used in the manufacture of building materials and household products. It is known for its preservatives and adhesive properties, making it a common ingredient in particleboard, plywood and various coatings. However, formaldehyde is also a volatile organic compound (VOC) , which can pose health risks at high concentrations.

Source of formaldehyde in wood-plastic decking

The formaldehyde in WPC decking comes mainly from adhesives and resins used in the manufacturing process. WPC decking consists of a mixture of wood fiber and plastic polymers, which are bonded together using an adhesive. If these adhesives contain formaldehyde-based resins, such as urea-formaldehyde or phenol-formaldehyde, formaldehyde may be released in the finished product.

Health effects of formaldehyde

Exposure to high levels of formaldehyde can cause adverse health effects, ranging from eye, nose and throat irritation to more serious respiratory problems and an increased risk of certain cancers. Given these potential health risks, regulation and minimization of formaldehyde emissions from building materials are critical.

WPC deck formaldehyde regulation

To ensure consumer safety, several international standards regulate the amount of formaldehyde emitted from building materials, including wood-plastic decking. One such standard is China’s national standard GB/T 24508 -2020, which sets strict limits on formaldehyde content in wood-plastic composite products. According to this standard, the formaldehyde content of wood-plastic deck must be less than 0.2 mg/l, which is lower than E0 level of European formaldehyde release standard.

Ensure low formaldehyde emissions from wood and plastic decking

WPC decking manufacturers can do a variety of things to minimize formaldehyde emissions:

Use of low-formaldehyde adhesives: using adhesives with low or no formaldehyde content, such as those based on polyurethane or other synthetic resins, can significantly reduce formaldehyde emissions.

Quality Control and testing: regular testing of formaldehyde emissions from WPC products helps ensure compliance with safety standards. This involves internal testing and third-party certification.

Consumer Awareness: educating consumers about the possible presence of formaldehyde in wood-plastic decking and providing information on measures taken to minimize emissions contribute to confidence-building and transparency.

Conclusion

Formaldehyde emission from wood-plastic decking is a key issue that needs to be addressed to ensure consumer safety and environmental sustainability. By complying with strict regulations and adopting best manufacturing practices, the industry can provide safer and healthier building materials. As consumers, it is important to choose products that meet accepted safety standards and to be aware of the materials used in construction projects at all times.

By understanding the sources, impacts and regulations of formaldehyde in wood-based decking, manufacturers and consumers can contribute to a safer and more sustainable living environment.

Leave A Comment