The general price of WPC (Wood Plastic Composite) tubes can vary depending on several factors, including:

– Size and dimensions of the tube (length, diameter, and thickness).

– Quality and composition of the WPC material (proportion of wood fibers to plastic, additives like UV stabilizers or anti-fungal treatments).

– Brand and manufacturer.

– Location and shipping costs.

– Quantity purchased (bulk purchases may offer discounts).

Typical Price Range

On average, WPC tubes are priced between $2 to $10 per linear foot. This price range may vary based on the above factors.

For example:

– Smaller or thinner tubes (used for non-structural applications like decorative trim or fencing) can be on the lower end of the price spectrum, around $2 to $4 per linear foot.

– Larger, thicker tubes or those designed for structural applications (like railings, supports, or outdoor furniture frames) may cost between $5 to $10 or more per linear foot.

—

Factors Influencing Price:

- Size and Thickness:

– Larger and thicker WPC tubes require more material and are generally more expensive.

- Quality of Material:

– High-quality WPC products, especially those with better wood-plastic ratios and enhanced durability (e.g., UV protection, waterproofing, anti-scratch coating), tend to be more expensive.

- Application:

– Structural WPC tubes designed to bear weight or for outdoor construction projects tend to be pricier than non-structural or decorative tubes.

- Brand and Manufacturer:

– Premium brands that focus on high-performance composites often charge higher prices due to product consistency, testing, and warranties.

- Region:

– Prices can vary depending on your location. Shipping costs may also influence the final price, particularly for bulk purchases.

- Bulk Discounts:

– Many suppliers offer discounts for large-volume purchases. Buying in bulk can reduce the per-foot cost, making it more economical for large projects.

—

For accurate pricing, it’s best to check with local suppliers or online retailers, as the price may also vary depending on the project size, customization options, and specific product features.

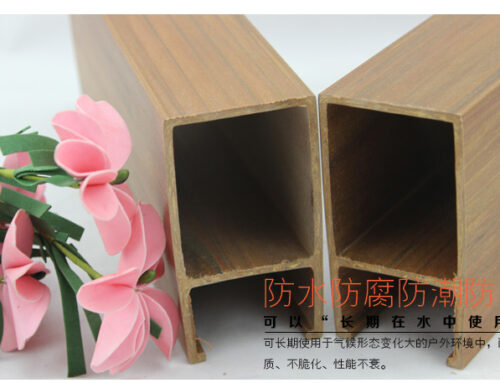

How to judge the quality of WPC tube?

Judging the quality of WPC (Wood Plastic Composite) tubes is essential to ensure you’re getting a product that will meet your performance expectations and last over time. Here are key factors to consider when evaluating the quality of WPC tubes:

- Material Composition

– Wood Fiber Ratio: A higher wood fiber content generally indicates better quality. Look for products that use a balanced mix of wood fibers and plastic. Typically, a ratio of 30-60% wood fiber is common for high-quality WPC.

– Type of Plastic: The type of plastic used (PVC, HDPE, etc.) can affect durability. For example, HDPE (High-Density Polyethylene) offers greater durability and impact resistance compared to other plastics.

- Surface Finish

– Texture: Quality WPC tubes should have a smooth finish that resembles natural wood or a textured surface for better grip and aesthetics. Check for uniformity in texture.

– Color Consistency: Inspect the color of the tubes for consistency. High-quality WPC products will have even color distribution without significant variations or blemishes.

- Resistance to Environmental Factors

– UV Resistance: Quality WPC tubes should have UV stabilizers to prevent fading and degradation from sunlight exposure. Check product specifications for UV resistance ratings.

– Moisture Resistance: WPC is generally moisture-resistant, but the best products will explicitly state their resistance to water absorption and mold growth. Look for products that have been tested for moisture resistance.

- Weight and Density

– Weight: Heavier WPC tubes often indicate a higher density and better quality. Light tubes may contain more plastic and less wood, which could affect durability.

– Density Measurement: High-density WPC typically offers better strength and durability. Ask for density specifications when comparing products.

- Certifications and Testing

– Industry Certifications: Check for certifications such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization) that indicate the product meets certain quality standards.

– Performance Tests: Look for products that have undergone independent testing for impact resistance, bending strength, and thermal expansion. Results should be available in product documentation.

- Manufacturer Reputation

– Brand Reliability: Research the manufacturer’s reputation in the market. Established brands are often more reliable in terms of quality control and customer service.

– Warranty and Support: Check if the manufacturer offers a warranty. A longer warranty period often indicates confidence in the product’s durability and performance.

- Customer Reviews and Feedback

– Consumer Feedback: Look for customer reviews and ratings online. Positive feedback and high ratings can be good indicators of quality.

– Installation Experiences: Pay attention to comments about installation ease and performance over time, as these insights can reveal product strengths and weaknesses.

- Price Point

– Cost vs. Quality: While a lower price might be tempting, it can sometimes indicate lower quality. Compare prices across similar products while keeping an eye on features and specifications. Higher-quality WPC tubes may have a higher upfront cost but can be more cost-effective in the long run due to their durability.

- Aesthetic Considerations

– Design Options: High-quality WPC tubes often come in a variety of designs and colors that mimic natural wood. Choose options that align with your aesthetic preferences and project requirements.

—

Summary of Key Quality Indicators for WPC Tubes:

– Material Composition: Check the wood fiber ratio and type of plastic used.

– Surface Finish: Look for a smooth or textured finish with uniform color.

– Environmental Resistance: Verify UV and moisture resistance.

– Weight and Density: Assess weight and inquire about density measurements.

– Certifications: Look for industry certifications and performance test results.

– Manufacturer Reputation: Research brand reliability and warranty offerings.

– Customer Reviews: Read feedback for insights into performance and satisfaction.

– Price Point: Balance cost with quality features to ensure value.

By considering these factors, you can effectively judge the quality of WPC tubes and select products that will meet your needs for durability, performance, and aesthetics.

Leave A Comment