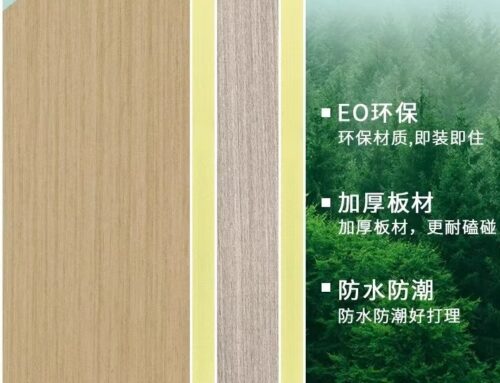

The **SPC (Stone Plastic Composite) Co-Extrusion Bamboo Charcoal Wall Panels** are made from a combination of advanced materials that enhance both performance and aesthetics. Here’s a breakdown of the materials used in these panels:

### **1. Stone Plastic Composite (SPC):**

– **Calcium Carbonate (Stone Powder):** The core material of SPC panels is a mixture of finely ground calcium carbonate (stone powder) and a polymer base. This gives the panels their **strength**, **density**, and **durability**. The stone powder helps create a rigid and impact-resistant material that is ideal for wall cladding.

– **PVC (Polyvinyl Chloride):** PVC is the main plastic material in SPC panels. It is mixed with stabilizers, plasticizers, and other additives to enhance the panel’s **flexibility**, **impact resistance**, and **waterproof** properties.

– **Other Additives:** The mix may include other stabilizers, anti-aging agents, flame retardants, and plasticizers that contribute to the panel’s resistance to heat, wear, and environmental stress.

### **2. Bamboo Charcoal Layer:**

– **Bamboo Charcoal:** The unique feature of SPC **co-extrusion bamboo charcoal panels** is the **bamboo charcoal** layer applied to the surface. Bamboo charcoal is made by burning bamboo at high temperatures in a low-oxygen environment, which turns the bamboo into a porous, odor-absorbing material.

– **Bamboo Charcoal’s Benefits:** This layer not only gives the panels a natural, textured finish but also provides the following benefits:

– **Air Purification:** Bamboo charcoal is known for its ability to absorb odors and volatile organic compounds (VOCs), making it a natural air purifier.

– **Antibacterial & Antimicrobial Properties:** Bamboo charcoal helps inhibit the growth of mold, bacteria, and fungi, making it especially beneficial in damp or humid areas.

– **Moisture Absorption:** Bamboo charcoal has hygroscopic properties, meaning it can absorb and regulate moisture, further preventing mold and mildew buildup.

### **3. Co-Extrusion Layer:**

– **Protective UV & Wear Layer:** In the **co-extrusion** process, a layer is added over the bamboo charcoal surface to provide an additional level of protection. This layer is typically made from **UV-resistant PVC** or other polymers that protect the panel from fading, discoloration, and wear due to sunlight exposure.

– **Scratch & Stain Resistance:** This outer layer enhances the panel’s resistance to scratches, stains, and abrasions, making it suitable for high-traffic areas.

### **4. Decorative Film (Optional):**

– Some SPC co-extrusion bamboo charcoal panels also include a **decorative film** beneath the bamboo charcoal layer. This film allows manufacturers to create a variety of textures and designs, such as wood, stone, or marble finishes. The decorative film provides the aesthetic appeal of natural materials while maintaining the durability and low maintenance of SPC.

—

### **Summary of Materials in SPC Co-Extrusion Bamboo Charcoal Wall Panels:**

– **Core Material:**

– **Stone Powder (Calcium Carbonate)**

– **Polyvinyl Chloride (PVC)**

– **Bamboo Charcoal Layer:**

– Bamboo charcoal, known for its odor-absorbing, air-purifying, and antimicrobial properties.

– **Protective Co-Extrusion Layer:**

– UV-resistant and wear-resistant polymer coating.

– **Decorative Film (optional):**

– For added texture and design variety (wood, stone, marble, etc.).

This combination of materials results in a **highly durable**, **eco-friendly**, and **low-maintenance** wall panel that offers both functional and aesthetic benefits.

Leave A Comment