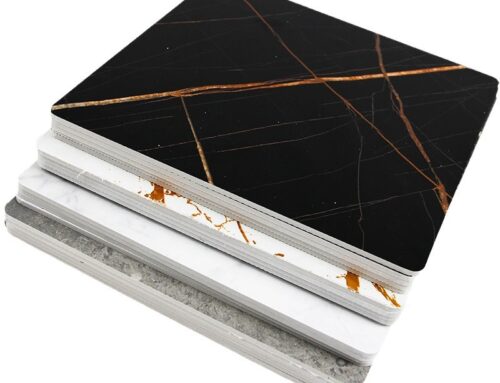

UV marble sheets are typically made from a combination of synthetic materials designed to mimic the appearance of natural marble while being more lightweight, durable, and cost-effective. The main materials used to create UV marble sheets include:

- Acrylic (PMMA – Polymethyl Methacrylate): This is one of the most common materials for UV marble sheets. It has a glossy finish and is often chosen for its durability, light weight, and ease of fabrication.

- PVC (Polyvinyl Chloride): Some UV marble sheets are made from PVC, which is known for its flexibility and ease of maintenance. PVC sheets are often used in areas where cost is a significant consideration.

- Composite Materials (Resins & Fillers): A mixture of resins (such as polyester or epoxy) and fillers (such as calcium carbonate or marble dust) is sometimes used to create a marble-like appearance. This helps to increase strength and create a more realistic texture and finish.

- UV-Resistant Coating: The “UV” in UV marble sheets refers to the ultraviolet-resistant coating applied to the surface. This coating is typically made from a UV-curable resin that helps to protect the material from sunlight and UV damage, making it more suitable for use in outdoor or sun-exposed environments.

These materials are molded or pressed into sheets that can then be cut and shaped for use in applications such as wall cladding, countertops, flooring, and decorative elements. UV marble sheets combine the aesthetic appeal of marble with the advantages of modern synthetic materials.

Leave A Comment