When comparing the durability of WPC (Wood Plastic Composite) tubes and solid wood tubes, several key factors should be considered, including moisture resistance, weather resilience, maintenance needs, and overall longevity. Here’s a breakdown of the key differences between the two in terms of durability:

- Moisture Resistance

– WPC Tube:

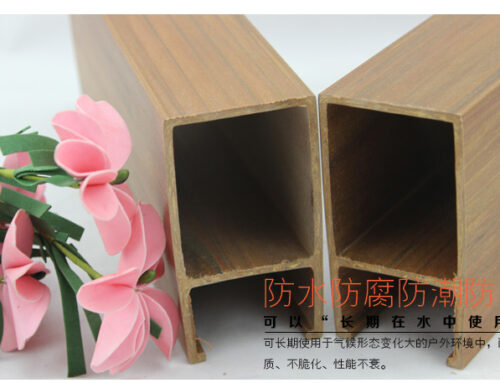

– Highly Moisture-Resistant: WPC is made from a combination of wood fibers and plastic polymers, which makes it highly resistant to water absorption. This prevents problems like swelling, warping, or rotting that can occur in environments with high moisture, such as outdoor or humid areas.

– No Rotting: WPC tubes do not rot or decay, even in prolonged exposure to moisture, making them more suitable for outdoor applications like decking, fencing, and structural tubes in wet conditions.

– Solid Wood Tube:

– Vulnerable to Moisture: Solid wood is prone to moisture absorption, which can cause swelling, warping, cracking, or rotting if not properly sealed and maintained. Over time, wood exposed to moisture without protection will degrade.

– Rot and Decay: Without regular treatment (e.g., staining, painting, or sealing), solid wood can rot, especially when used in outdoor applications or high-humidity environments.

Winner: WPC tubes are significantly more moisture-resistant and durable in wet environments than solid wood.

—

- Insect and Pest Resistance

– WPC Tube:

– Insect-Resistant: Due to its plastic component, WPC is resistant to termites, borers, and other pests that typically damage wood. The synthetic aspect of WPC prevents insects from feeding on or nesting within the material.

– Solid Wood Tube:

– Insect Vulnerability: Wood is naturally vulnerable to termite and insect infestation. Without chemical treatment, solid wood can be compromised by pests, especially in outdoor environments or areas where termites are prevalent.

Winner: WPC tubes have better resistance to insect damage compared to solid wood tubes.

—

- Weather and UV Resistance

– WPC Tube:

– UV and Weather Resistant: WPC materials are generally manufactured with UV stabilizers, making them more resistant to sunlight, fading, and cracking due to prolonged exposure to the elements. WPC tubes are less likely to deteriorate or change color due to sun exposure.

– Better Performance in Extreme Temperatures: WPC materials are more resistant to temperature fluctuations and perform well in both hot and cold climates without cracking or warping.

– Solid Wood Tube:

– Requires Protection from UV and Weather: Solid wood tubes can suffer from fading, splitting, and warping if exposed to UV rays and weather without proper protection. Wood requires regular maintenance, such as sealing or painting, to prevent damage from sunlight and weather changes.

Winner: WPC tubes perform better in weather resistance and UV exposure compared to solid wood, which requires more maintenance and protection.

—

- Maintenance Requirements

– WPC Tube:

– Low Maintenance: WPC requires very little maintenance beyond occasional cleaning with water and mild soap. It does not require regular sealing, painting, or treatment to maintain its appearance or durability.

– Solid Wood Tube:

– High Maintenance: Solid wood requires ongoing maintenance, including sealing, painting, or staining, to protect it from moisture, UV damage, and insects. Without this maintenance, wood will degrade over time, making it less durable.

Winner: WPC tubes have a clear advantage in terms of lower maintenance needs.

—

- Structural Strength

– WPC Tube:

– Good Rigidity but Limited Load-Bearing Capacity: WPC has good rigidity and durability for many applications, but its structural strength is typically lower than solid wood in heavy-load situations. WPC tubes are suitable for medium-strength applications like decking, fencing, or railings but may not hold up as well as solid wood in heavy structural roles.

– Solid Wood Tube:

– High Strength: Solid wood, especially hardwood species, has superior load-bearing capacity and is more suitable for applications requiring high structural strength, such as beams, posts, and other construction elements.

Winner: Solid wood tubes are stronger in terms of load-bearing capacity, but WPC is often adequate for most non-structural or light structural applications.

—

- Longevity and Overall Durability

– WPC Tube:

– Long Lifespan: With proper installation, WPC tubes can last 15 to 25 years or more, particularly in outdoor applications. Their resistance to moisture, pests, and weather helps them maintain their structural integrity and appearance over time with minimal maintenance.

– Solid Wood Tube:

– Varied Longevity: The lifespan of solid wood tubes depends heavily on maintenance and environmental conditions. With proper care (regular sealing and protection from elements), solid wood can last for decades. However, if left untreated, wood is more prone to degradation.

Winner: WPC tubes tend to have a longer service life in environments where moisture, insects, and weather are significant concerns. However, solid wood can last just as long or longer with proper maintenance.

—

- Environmental Impact

– WPC Tube:

– Eco-Friendly: Many WPC products are made from recycled materials, including recycled wood fibers and plastic, making them a more sustainable option. WPC is also recyclable, contributing to a more circular economy.

– Solid Wood Tube:

– Renewable: Wood is a renewable resource, and when sourced from sustainably managed forests, it can be an environmentally friendly option. However, the need for ongoing treatments and chemicals (such as pesticides or sealants) can lessen its environmental benefits.

Winner: WPC tubes may have a slight advantage in terms of sustainability, particularly when made from recycled materials, though sustainably harvested wood is also environmentally friendly.

—

Conclusion: Which is More Durable?

– WPC Tubes are generally more durable than solid wood tubes in environments where moisture, weather, pests, and low maintenance are key factors. WPC’s resistance to water, rot, UV exposure, and insects makes it ideal for outdoor and harsh conditions with minimal upkeep.

– Solid Wood Tubes, on the other hand, offer higher structural strength and natural aesthetic appeal, but they require regular maintenance to ensure longevity. In areas where load-bearing capacity is critical and proper maintenance can be provided, solid wood may be more appropriate.

Overall, for applications in moist or outdoor environments where minimal maintenance is desired, WPC tubes are the better choice in terms of durability. However, for applications requiring high structural strength, solid wood may be more suitable if well-maintained.

Leave A Comment